Imveliso ngokubanzi:

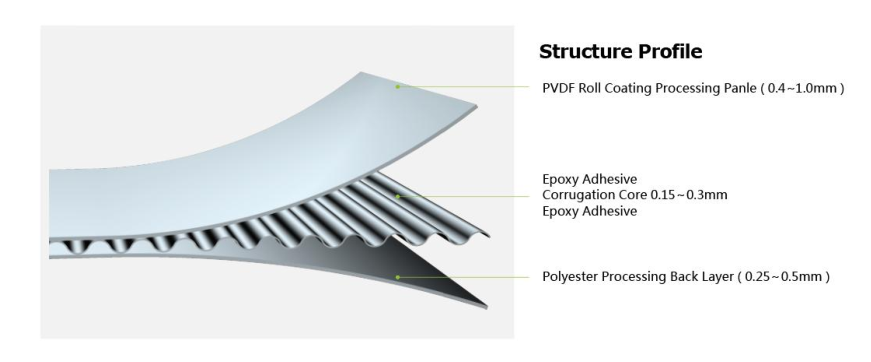

Iphaneli yeAluminiyam ehlanganisiweyo ehlanganisiweyo ikwabizwa ngokuba yi-aluminiyam egudisiweyo ipaneli ehlanganisiweyo, isebenzisa i-AL3003H16-H18 imathiriyeli yealluminiyam, enobuso be-aluminiyam ubukhulu 0.4-1.Omm, ubukhulu be-aluminium ezantsi 0.25-0.5mm, ubukhulu obuphambili 0.15-0.3mm. kumgca wemveliso ofanayo, usebenzisa i-thermosetting ye-resin ye-resin ehambelana nobuso kunye ne-aluminiyam ephantsi kwi-arc shape, ukwandisa amandla okunamathela, ube neepaneli zetsimbi ezigqwesileyo zokubambelela.

Iphaneli yeAluminiyam edityanisiweyo edityanisiweyo yokwenziwa okwesibini:

> ukusika

-I-Aluminium Corrugated Composite Panel yokusika kufuneka isebenzise umatshini wokusika okhethekileyo, usike ngokwesayizi eyilelweyo emva kokulungiswa kwiqonga elicaba.

- Umphetho wokusika kufuneka ulunge kakhulu kwaye ucoceke.

> Ukugroova

Inkqubo ebalulekileyo ekuqhubeni i-Aluminium Corrugated Composite Panel yi

grooving 0.15-0.2mm kwi ezantsi aluminiyam.Processing angle ncoma ukwenza

ialuminiyam esezantsi kunye nentsimbi engundoqo kunye kwi-engile ye-91 degree.

1)isarha yokulungisa iyafana nomfanekiso osembindini ongezantsi.Sebenzisa isarha ene-R5.5 kunye ne-angle engama-91.

isidanga.

2) Xa usenza igrooving enkulu, sebenzisa isarha yegrooving emfanekisweni kunye nokushukuma komatshini

izixhobo zokuphucula ukusebenza kakuhle kwemveliso.

I-Grooving: ngokwendlela yoyilo lomzobo, iindlela ezibuyisela umva kufuneka zisikwe

ngokomfanekiso wasekhohlo.

> Ukubumba

- Ukubunjwa emva kokugoba, lungisa imveliso kwiqonga elithile elisicaba,goba i-engile ye-90 degree kunye nesibambeli sokugoba ngokwetshati yoyilo.

-Inxalenye yekona yokugoba kufuneka ihlale ithe tye (qaphela ukuba ukuthintela ukwaphuka kwentonga kwikona, umsebenzi kufuneka uqhutywe ngaphezulu kwe-10°C.

- Ukugoba ubude obuyi-20 mm ubuncinane ngaphezu komphetho woyilo, le nxalenye ye-Angle enejeli ye-silica inokufikelela kwisiphumo esingcono sokungangeni kwamanzi kunye nezinye iimpawu.)

>Rola iSangqa

-Izidanga ze-arc zokusetyenzwa kwemveliso, sebenzisa ipleyiti ye-roller eqhelekileyo.

-Ukulungiswa kweemveliso ze-arc gcina i-100 mm iqala njengomlinganiselo.

- Xa uqengqeleka, awukwazi ukuyeka.

- Kufuneka ubeke ingqalelo kwicala, skrola i-arc yevili kunye nebhodi engundoqo kwicala elithe nkqo.

>Isaziso seGrooving

A) Ukugoba kabini kunye nokusika iprofayili ayihambelani

-Ukususa i-0.15-o.2mm kwiphepha langaphandle ngexesha lokugrumba.

-Ukugoba i-clamp ayifaki i-flange nzulu ngokwaneleyo.cebisa ukufaka i-clamp kwi-flange kubuninzi.

-I-Grooving idinga umsebenzisi onamava, cebisa ukusebenzisa igcisa elichwepheshile

- Ukungalingani koxinzelelo lomatshini wokugoba kubangela ukuba inxalenye egobileyo ingalingani, cebisa ukugcina uxinzelelo lomatshini wokusebenza luzinzile.

B)i-core material ixobula kwipaneli yobuso

-Xa ubona unobangela wokuxobula, nceda ujonge isarha yokusikwa phambi kokuba ilungiswe.

-Xa ucheba, musa ukuwela umgca ophakathi wegrooving, kungenjalo umphumo emva kokugoba awuyi kuhlangabezana nemfuneko yoyilo.

Isicelo: